A production order defines which material is to be processed, at which location, and at what time and how much quantity is required. It also defines which components and sequence of operations are to be used and how the order costs are to be settled.

Production Order creation is required to produce the material and consume the components which are used, and it also specifies the sequence of operations to be performed at the work center.

The release of order signifies that the order is ready to be executed at the shop floor. You can do an automatic release of order also during creation mode by using relevant production scheduling profile in the material master with auto release indicator set.

Step 1) From SAP Easy access screen open transaction CO01

Enter the material code for which production order needs to be created.

After filling in all the fields, click or press Enter to go to the next screen.

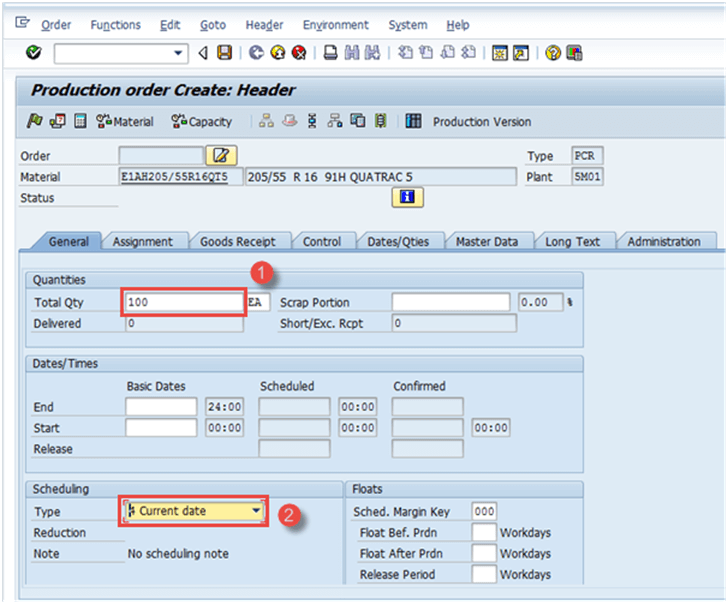

Step 2) In this Screen

After filling the entire fields press click to confirm, the system will then copy BOM and Routing data in the order.

Step 3) In the same screen,

Click to release the order. The following message will appear in the bottom left corner: .

Click to check material availability. The system will show the message regarding the availability of components.

Note: You can also decide not to release the order if there are missing parts found in availability checks.

![]()

Click button to save, the following message will show in the bottom left corner: .

Planned orders are the result of MRP run and should be converted to production order for further execution process.

You cannot directly declare production using planned orders and, therefore, it needs to be converted to Production Order.

Once, planned order is converted to production order, planned order gets deleted from the system and is no longer available to be considered in MRP (Material Requirement Planning).

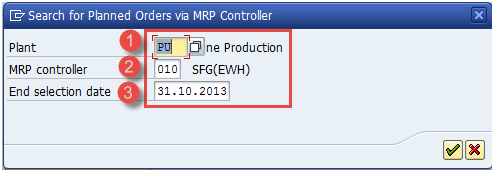

Step 1) From SAP Easy access screen open transaction MD16

The system will show the screen as below.

Step 2) In this screen, we will fetch the planned orders based on MRP controller and selection dates.

Click right mark sign from the bottom or enter from the keyboard to move to the next screen.

Step 3)In this screen,

Production orders will be created after conversion of planned orders.

You might require to change production order incase if your business wants to change some planning quantity or if BOM/Routing has been changed after the order has already been created.

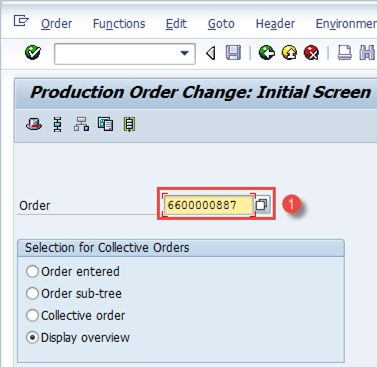

Step 1) From SAP Easy access screen open transaction CO02

Enter production order number which you want to modify.

In the same window you can see “Display Overview” button is selected, it is selected by default.

After filling in all the fields, click to go to the next screen.

Step 2) In this screen, the order will be modified.

After finishing all modifications, click button to save the order. The system will show a message like Order number saved 6600000887 at the lower left corner.

Step 1) From SAP Easy access screen open transaction CO15, three activities occur at the same time with confirmation.

After filling in all the fields, click to go to the next screen

Step 2) In this screen, we will enter the actual yield quantity to be confirmed.

Step 3) In this screen, you will see the goods receipt of parent material and goods issue of components.

If the control key of the last operation in the order specifies automatic goods receipt, the system automatically posts the produced material to unrestricted stock.

Automatic goods receipt can also be activated by the production scheduling profile in the material masterwork scheduling view.

If you confirm an order with components that have the Backflushing indicator set in the material master MRP1 view, the system automatically posts a goods issue (GI) for these components.

Click button to save.

![]()

The system will show a message like at the lower left corner, to hint how many goods movement are posted successfully or failure.

Failed goods movements due to a deficit of stock for consumption are reprocessed manually.

Technical completion of the order is required when production order is either fully delivered, or it is not to be processed further at shop floor.

After technical completion order status changes to TECO, no further goods movement can be done against the order.

Order is no longer available in MRP run and gets deleted from stock/requirement list.

The controlling department can then carry out the variance calculation on the production Order after TECO status.

Step 1) From SAP easy access, open transaction CO02

Click to next screen after filling all fields,

Step 2) In this screen, we will see how to place production order to TECO status,

Troubleshooting

BOM and Routing must exist before creation of production order else it will not be copied into the production order and can cause issues in planned costs updation and consumption of components during confirmation process thereby impacting the inventory of the components.

Production order must be released before doing order confirmation as the released status of the order allows confirmation to happen.

If you receive any Accounting error during goods movement in the confirmation process, then ensure the right valuation class is set in the material master Accounting view or contact Finance team.

Ensure that standard cost for the material is updated to avoid any costing related errors such as activity price missing etc. during production order confirmation.

If some goods movement gets failed during confirmation process due to the stock deficit, then you should process them separately once components are brought to stock.